truck mounted winches

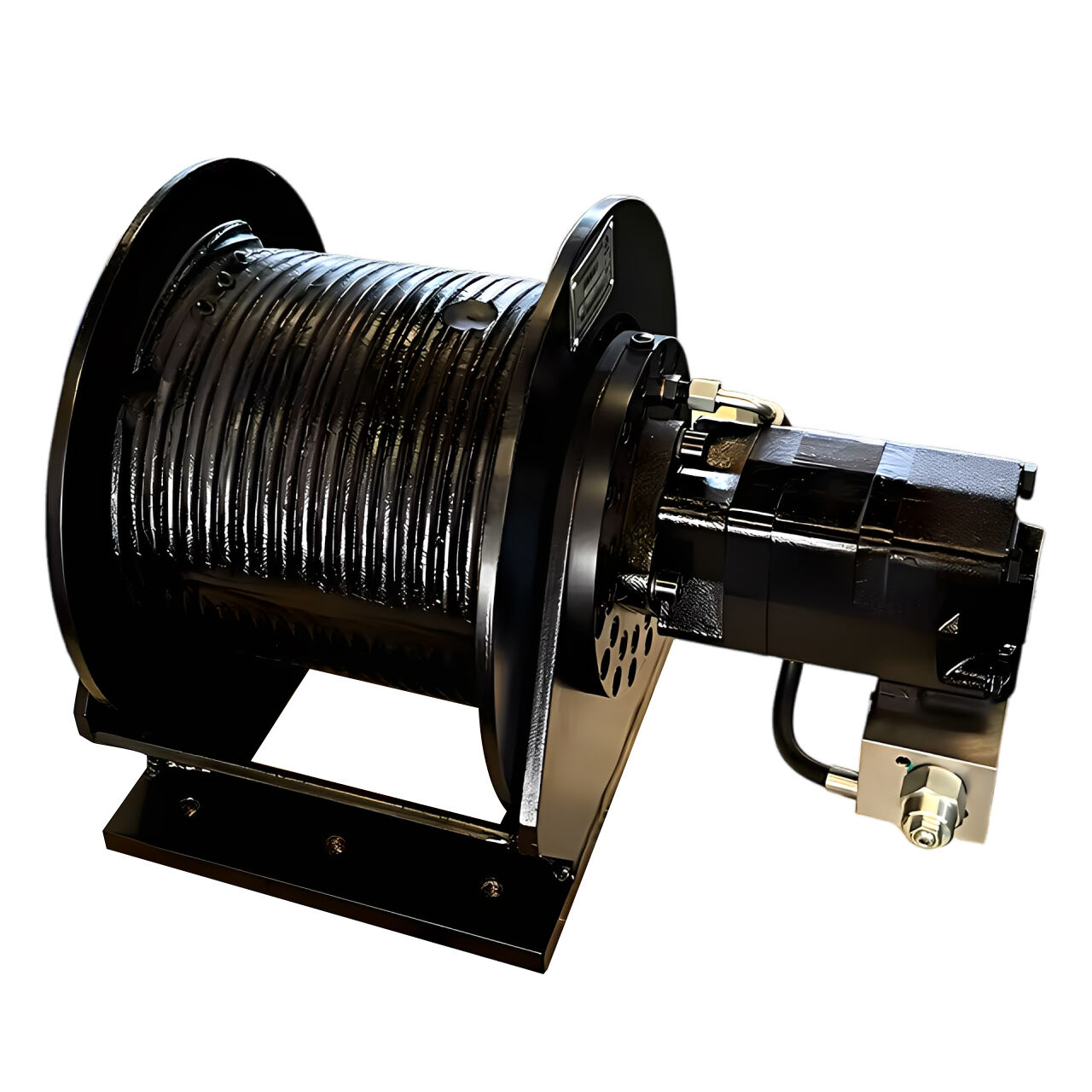

Truck mounted winches represent a crucial advancement in heavy-duty vehicle equipment, combining robust pulling power with versatile mounting capabilities. These specialized mechanical devices are engineered to be permanently installed on trucks, offering exceptional pulling and lifting capabilities for various industrial applications. The winch system typically consists of a drum around which wire rope or cable is wound, powered by either hydraulic, electric, or mechanical systems. Modern truck mounted winches feature advanced safety mechanisms, including automatic braking systems, load-holding capabilities, and emergency stop functions. The winches are designed with precision-engineered gear systems that provide optimal torque multiplication, enabling them to handle loads ranging from 8,000 to 50,000 pounds or more. These systems are particularly valuable in construction, recovery operations, and utility work, where their reliable pulling power is essential. The mounting configuration is specifically designed to distribute force evenly across the truck's frame, ensuring structural integrity during heavy-duty operations. Additionally, many contemporary models incorporate remote control capabilities, allowing operators to maintain safe distances during winching operations while maintaining precise control over the equipment.