מדריך חשוב לפתרונות מגני פינות למשלוחים

הגנה על מטען יקר ערך במהלך ההובלה היא דאגה מרכזית bagiliers ולוחמי שיפוד בעולם. מגיני פינה מגיני פינות למטענים ממלאים תפקיד חשוב בהגנה מפני נזק, הפחתת טענות ובטיחות שהמוצרים יגיעו ליעדם בשלמות. עם מגוון חומרים, גדלים ועיצובים זמינים בשוק, בחירת פתרון ההגנה המתאים דורשת שיקול דעת של מספר גורמים.

תעשיית התחבורה מתמודדת עם מיליארדים של איבודים מדי שנה עקב נזקי מטענים, כאשר נזקים בפינות ובקצוות מהווים חלק משמעותי מהמקרים. על ידי יישום נכון של מגיני פינה למטענים, חברות יכולות לצמצם בצורה משמעותית את האיבודים הללו תוך שמירה על המוניטין שלהן כשירות אמינה לאספקה.

הכרת חומרי מגני פינה

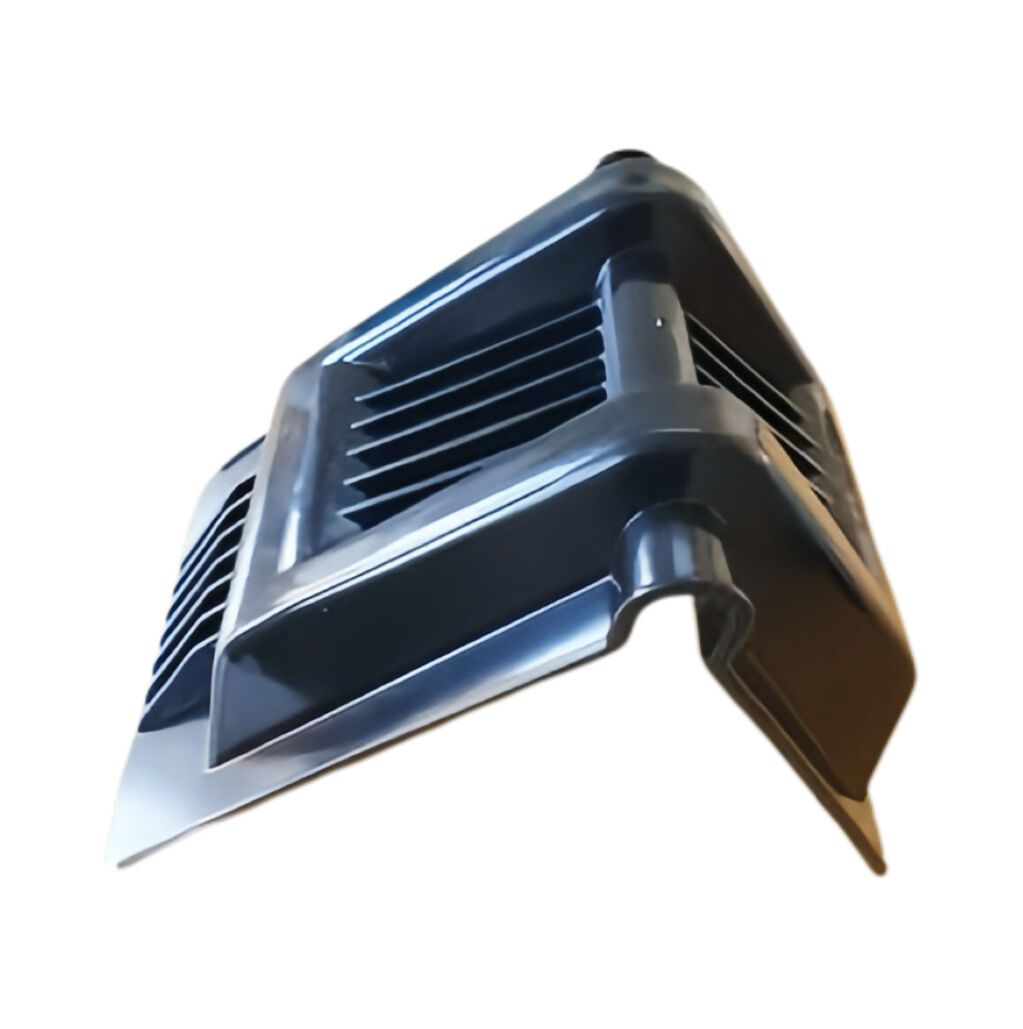

מגני פינה מפלסטיק

מגני פינה מפלסטיק למטענים מציעים שילוב מצוין של עמידות ויעילות עלות. פתרונות קלי המשקל אלו מתאימים במיוחד לתנאי שינוע סטנדרטיים ומספקים הגנה אמינה מפני כוחות תקיפה ודחיסה. מגני פלסטיק מודרניים מיוצרים לעתים קרובות מחומרים מחזוריים, מה שהופך אותם לבחירה בעלת אחריות סביבתית.

היתרונות של מגני פלסטיק כוללים את היכולת לשימוש חוזר, שכן הם יכולים לעמוד במספר מחזורי שינוע כאשר מתוחזקים כראוי. בנוסף, תכונות ההתנגדות למזג האוויר הופכות אותם לאידיאליים למגוון מצבים של אחסון, גם ב помещения וגם בחוץ.

פתרונות מבוססי קרטון ונייר

לעסקים בעלי דאגה סביבתית, מגיני פינות מקרטון ונייר מהווים אפשרות ברת קיימא. פתרונות זהים ניתנים להריסה טבעית, מציגים חוזק מפתיע, וניתן להתאימם לצרכי המטען הספציפיים. אם כי הם אולי לא יהיו עמידים כמו חלופות מפלסטיק לשימוש חוזר, הם מצטיינים ביישומים של טיול אחד.

חדשנות אחרונה בתחום ההגנה המבוססת על נייר geführt להגברת העמידות באמצעות מבנה רב-שכבות וטיפולים מיוחדים של חיפוי, מה שמשפר בצורה משמעותית את הביצועים בתנאי שינוע שונים.

הגנה על פינות ממתכת

יישומים כבדים דורשים לעתים קרובות את החוסן העליון של מגני פינות מתכת עבור מטען. בדרך כלל מיוצרים מפלדה או אלומיניום, פתרונות חזקים אלה מספקים הגנה מקסימלית עבור מטען כבד מאוד או בעל ערך. עמידותם הופכת אותם לאידיאליים למסלולי שיט רגילים שבהם מגנים חוזרים ומשתמשים מחדש.

ההשקעה הראשונית במגני מתכת עשויה להיות גבוהה יותר, אך אורך חייהם ביצועים אמינים שלהם לעתים קרובות מובילים ליעילות בעלויות ארוכת טווח טובה יותר עבור פעולות שיט בכמויות גבוהות.

היקף ותנאים של התאמה

אפשרויות גודל סטנדרטיות

בחירת מגני פינות בגודל הולם עבור מטען היא קריטית להגנה יעילה על מטען. גדלים סטנדרטיים נעים בדרך כלל בין 2 ל 6 אינץ'באורך הרגל, עם עובקות שונות כדי להכיל משקולות עומס שונות. המפתח הוא להבטיח כיסוי מלא של אזורי הפינות הפגיעים תוך שמירה על תקינות בטוחה.

בעלי מקצוע בלוגיסטיקה ממליצים לבחור מגנים עם רגליים שאורכן מעט גדול מאורך המינימום הנדרש, כדי לקחת בחשבון הזזות קלות במהלך הנסיעה ולספק כיסוי הגנה אופטימלי.

פתרונות התאמה אישית של מידות

כאשר גדלים סטנדרטיים אינם עומדים בדרישות ספציפיות, מגני פינות בהתאמה אישית למטענים מציעים הגנה מותאמת אישית למידות מטען ייחודיות. פתרונות בהתאמה אישית מבטיחים התאמה מושלמת והגנה מקסימלית עבור חבילות לא סטנדרטיות או מכולות משלוח מיוחדות.

עבודה עם יצרנים לפיתוח פתרונות מותאמים אישית להגנה על פינות מובילה לעיתים קרובות לשיפור היעילות בפעולות האריזה ולהגנה כוללת טובה יותר עבור תצורות מטען ייחודיות.

מאפיינים וمواصفات ביצועים

יכולת נשיאה

הבנה של דרישות המשקל היא עניין חיוני בבחירת מגני פינות לשילוח מטענים. חומרים ועיצובים שונים מציעים יכולות שונות להחזקת עומס, ממוצרים קלי משקל המתאימים לאריזות סטנדרטיות ועד לפתרונות כבדי משקל המסוגלות לתמוך בכמה טונות של לחץ איחזור.

בדיקות מקצועיות הראו שמגני פינות בעלי דירוג נכון יכולים להגביר את חוזק האיחסון בערימה עד 400%, ובכך שיפור משמעותי בשימוש במרחב המחסן וביעילות השינוע.

עמידות בפני התנגשויות

עמידות בפני תקלות היא תכונה קריטית של מגני פינות יעילים לשילוח מטענים, במיוחד בסביבות שבהן הטיפול במטען כולל שימוש בציוד מכני. מגני פינות איכותיים צריכים לספוג ולפזר את כוחות המכה כדי למנוע נזק לפינות המוגנות.

פתרונות מודרניים להגנת פינות כוללים לעיתים תכונות עיצוב מיוחדות כגון שוליים מחוזקים ואזורים בולעי זעזועים כדי לחזק את עמידותם בפני תקלות.

יישום ומיטב התactices

טכניקות התקנה

התקנת מתאמים פינה נכונה לשילוח משלוחים היא עיקרית להגנה מקסימלית. התהליך צריך לכלול יישור זהיר עם פינות החבילה וחיבור איתן באמצעות רצועות או שיטות הדבקה מתאימות. הדרכת עובדים בפרוצדורות ההתקנה הנכונות עוזרת להבטיח הגנה עקבית בכל המשלוחים.

ביקורות תקופתיות של פרקטיקות התקנה ותוצאותיהן עוזרות לשמור על תקנים גבוהים ולזהות הזדמנויות לשיפור באסטרטגיות הגנת פינות.

תחזוקה ובדיקה

בדיקה תקופתית של מתאמי פינה ניתנים לשימוש חוזר לשילוח משלוחים עוזרת לשמור על יכולות ההגנה שלהם ולהאריך את משך החיים שלהם. הקמת קריטריונים ברורים להערכת שחיקה ונזק מבטיחה החלפה בזמן של מתאמים פגומים לפני שנכשלים בשימוש.

יישום תוכנית תחזוקה שיטתית, הכוללת ניקוי ואחסון נכון של מתאמי פינה בין שימושים, משפיעה משמעותית על אורך החיים שלהם ועל אמינות הביצועים.

שאלות נפוצות

כמה זמן מתאמי פינה שומרים לרוב?

אורך החיים של מגני פינות לשינוע משתנה בהתאם לסוג החומר ותנאי השימוש. מגנים מפלסטיק וממתכת יכולים לשרוד מספר חודשים עד שנים עם טיפול תקין, בעוד שגרסאות מקרטון מיועדות בדרך כלל לשימוש חד-פעמי. בדיקה תקופתית ושימוש נכון מאריכים בצורה משמעותית את אורך החיים היעיל שלהם.

מהן ההשלכות הסביבתיות של חומרי מגני הפינה השונים?

מגני פינה מקרטון ומבסיס נייר הם ביודלקים לחלוטין וניתנים להחזרה. אופציות מפלסטיק מכילות לעתים קרובות חומר מחזור וניתנות להחזרה בסוף מחזור החיים. למגני מתכת יש את אורך החיים הארוך ביותר וניתנים להחזרה באופן מלא, אם כי יש צורך באנרגיה רבה יותר לייצורם הראשוני.

כיצד תנאי מזג האוויר משפיעים על ביצועי מגני הפינה?

עמידות למזג האוויר משתנה בהתאם לסוג החומר. מגני פינה מפלסטיק וממתכת לשינוע שומרים על ביצועיהם ברוב תנאי מזג האוויר. אופציות מבוססות נייר עשויות להידרש הגנה נוספת מפני מזג אוויר בתנאים רטובים. טמפרטורות קיצוניות עלולות להשפיע על סוגי פלסטיק מסוימים, ולכן יש לקחת בחשבון את תנאי האקלים בבחירת החומר.